DESS® ACTIVE HEX® | The Zero Waste Implant

ACTIVE HEX® | The Implant that ensures Excellent Primary Stability

We are delighted to present DESS® ACTIVE HEX®, the ideal implant for clinical cases that require immediate loading.

Being fully compatible with NobelActive®, DESS® ACTIVE HEX® offers excellent primary stability, especially in soft bone, extraction sockets or the aesthetic region.

Apical & Self-tapping cut Design

DESS® ACTIVE HEX® Apical Design with twin cutting blades facilitates insertion into challenging anatomical sites thus offering exceptional primary stability in demanding situations.

Additionally, the ACTIVE HEX® has excellent cutting capabilities due to the Self-tapping cut Design with reverse cutting flutes, making it an excellent choice for hard bone.

These design characteristics enable the positioning of the implant to be adjusted during placement.

Discover all ACTIVE HEX® components available.

ACTIVE HEX® | Groundbreaking Design

The design characteristics of the DESS Implant provide efficiency, durability and stability, allowing it to achieve unparalleled results. Consequently, DESS® ACTIVE HEX® is the best choice for dental professionals, especially in cases where primary stability is key.

Discover the features and advantages that make ACTIVE HEX® the perfect choice for implant treatment.

The HEX Connection | Dual Function

• Hexagonal Interlocking with 6 positions for a firmer connection with superior mechanical strength.

• Internal Conical Connection at 12o, creating the ultimate seal whilst reducing the possibility of micromovements.

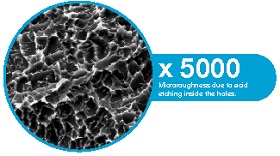

OST® by DESS® | Osseointegration Surface Technology

ACTIVE HEX® surface has been subjected to a double treatment of sandblasting and acid etch that assures optimal bone growth.

DESS® Osseointegration Surface Technology complies with SLA standards and is achieved by using two different processes which, when combined, present a double range roughness composed of large “holes” due to sandblasting,

and microroughness due to acid etching,

making this double treatment the optimal surface topography for osseointegration.

Coldworked Titanium Grade IV

ACTIVE HEX® is composed of cold worked Titanium Grade 4 for superior mechanical resistance.

The Collar

ACTIVE HEX® has a mechanised smooth collar with inverted conical shape and micro-rings.

-

- A mechanised smooth collar provides spaces for additional marginal bone and is easy to clean and maintain in case of exposed threads.

- The collar’s inverted conical shape and micro-rings may reduce early bone loss.

Double-lead thread entry

A double thread entry makes the insertion considerably easier, obtaining a faster insertion with less revolutions needed.

Variable thread thickness

A variable thread improves stability in cases of immediate implant placement.

• Apical thinner thread allows for faster cutting and penetration whilst it facilitates repositioning.

• Thicker upper thread improves bone compacting features.

The ACTIVE HEX® expanding body makes it possible to achieve gradual bone compression.

The Surgical Kit

- Designed to be simple and easy to use.

- Customisable to the different protocols arranging the drills as per the case needs.

- Drills available in 3 different lengths: 28mm, 33mm & 36mm.

- 100% compatible with the kits of the brand of reference.

Download the ACTIVE HEX® catalogue to get all the information about the surgical kit and its components.

Full range of Prosthetic Abutments

DESS Dental’s full portfolio of prosthetic abutments and relevant components is available for ACTIVE HEX®.

Furthermore, thanks to DESS® Pure Switch Concept, ACTIVE HEX® is 100% compatible with the ‘brand of reference’ abutments and components and can be used in combination with them.

The Zero Waste Implant

DESS® ACTIVE HEX®, along with DESS® CONICAL BLT, is The First Zero Waste Implant on the market.

DESS Dental’s commitment to Environmental Sustainability brings us to take action to reduce waste and our impact on the environment. This commitment is reflected in our ESG policy.

Now, we are going one step further by extending this philosophy to the product’s lifecycle: we have created The Zero Waste Implant with "infinite packaging".

How is the Zero Waste Implant achieved?

We have achieved the First Zero Waste Implant on the market by developing two different initiatives:

1. Reduction of the paper and plastic of our packaging to the minimum. Instead, we have introduced our ground-breaking Titanium vial. Why? Because a titanium vial can be sterilised and re-used multiple times, creating ZERO Waste.

2. Waste collection process that assures full recycling, guaranteeing no waste is generated from our packaging.

We recycle or re-use 100% of its packaging.

• 100% Recyclable cardboard box

• Widely Recyclable PET blister

• Titanium reusable and recyclable vial

The recycling cycle

We have come full circle by creating a process that ensures full sustainability of the product’s life cycle. We assume the integral collection of the packaging, making sure no waste is generated.

Go to The Zero Waste Implant page to discover more about it.

If you want to learn more about DESS® ACTIVE HEX®, you can visit the ACTIVE HEX® website, download the catalogue or head to this product’s section on our website. You can also contact us for more information at support@dessdental.com.