DESS tests

There are different types of tests to which our abutments are subjected. All the tests that we perform are developed under the strictest quality controls established by ISO, FDA and Canada Health.

Functionality test

Its mission is to check the pieces at their tolerance limit. To do this, we will put the products through their worst conditions and check if they still work properly in the original implant.

This test is very necessary to verify that all our products fit perfectly in the original implant system, making them easily interchangeable with the original connection abutments.

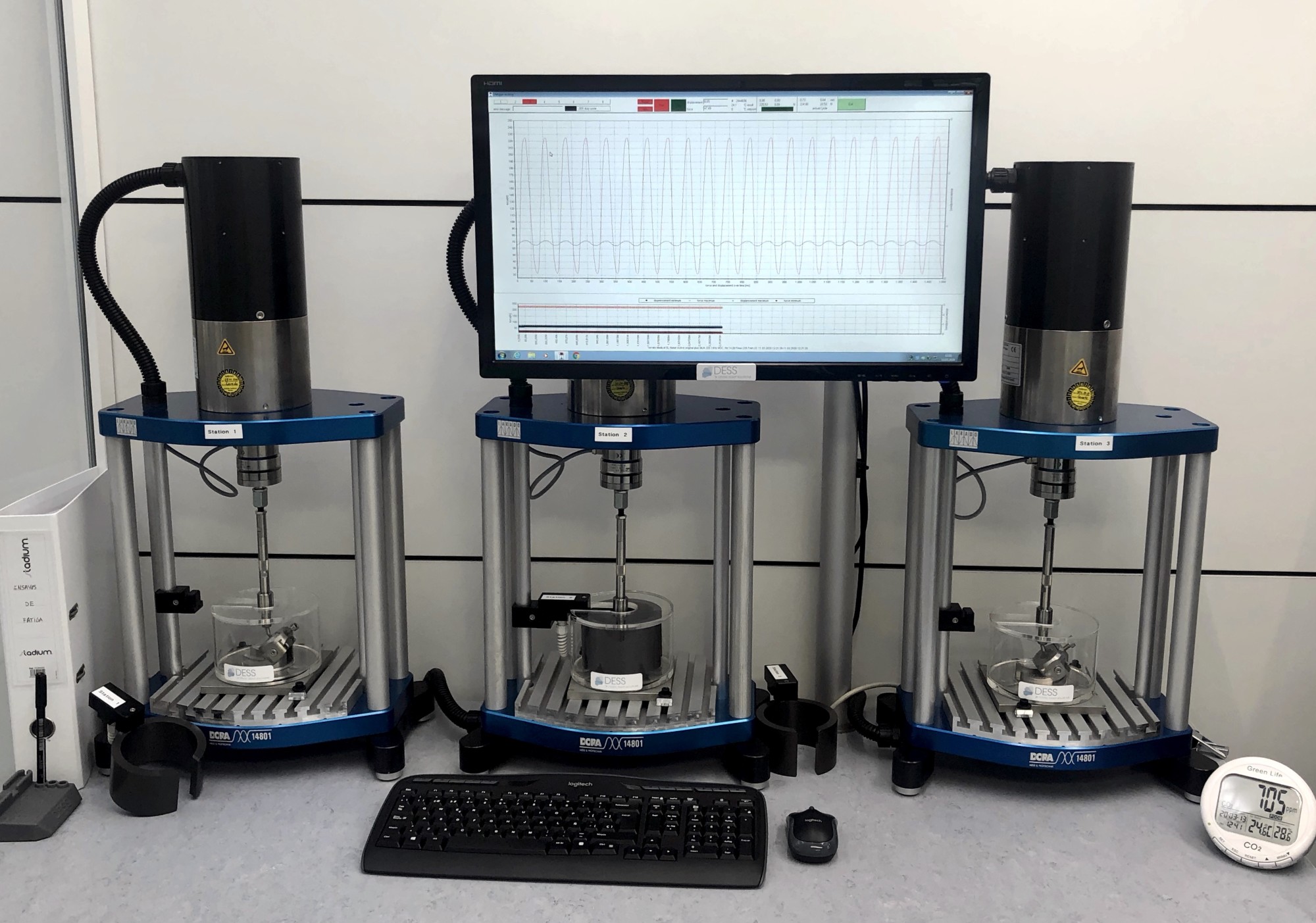

Fatigue test

This type of test is the best that can be done, as it allows us to see how our products react in performance. The fatigue test is carried out in accordance with ISO 14801.

The fatigue test consists in checking the resistance of the implant-prosthesis assembly in the worst conditions. Unlike the functionality test, the fatigue test is performed by subjecting the products to a combined compression-flexion movement, such as would be generated in the mouth, to ensure that they do not suffer any damage.

The ISO 14801 establishes that:

- Implant-prothesis combinations mounted in 30º off-axis orientation

- Cyclic force applied (frequency 14Hz)

- 5 million cycle duration

Wet fatigue test

With the wet fatigue test we try to simulate conditions in mouth. To do this, the piece is immersed in liquid at a temperature relatively similar to that of saliva and some friction is exerted on it to simulate movement in the mouth.

There is also the possibility of colouring the liquid to check the watertightness of the prosthetic connections. With this we will verify if the biological seal of the implant-prosthesis connection works correctly. If the biological seal fails, the internal connection will be painted.