Zero Waste DESS Implants | Innovation and Commitment to the Environment

At DESS, we are committed not only to excellence in dental solutions, but also to sustainability and care for the planet.

Our Zero Waste process that we apply to our DESS implants: ACTIVE HEX & CONICAL BLT, the first implant on the market that does not generate waste, reflects this commitment, making us leaders in the industry by integrating the most advanced and responsible recycling technology.

Benefits of Recycling: Caring for Our Future

Recycling is not only a responsible practice; it is an imperative need to protect the environment. Among its key benefits, we highlight:

Waste reduction in DESS

By recycling, we significantly reduce the amount of waste that ends up in landfills or contaminates ecosystems.

That is why DESS uses recycled materials in our packaging and also includes a vial of Titanium.

Conservation of natural resources in DESS

Reusing materials such as Titanium reduces mining and preserves valuable resources.

We recover and recycle the vial of Titanium included in our packaging, increasing its cycles of use.

Energy savings in DESS

Recycling materials requires less energy than producing them from scratch, thus reducing greenhouse gas emissions.

In DESS we have an ESG policy that includes different actions with which we care for and preserve the Environment.

Fostering a circular economy in DESS

By reintegrating recycled materials into new products, we support a model of sustainable production and consumption.

Our Zero Waste process is based on a circular economy of the packaging of our implants.

The Grade 5 Titanium Recycling System and the Recovery of Empty Vials

At DESS, with the Zero Waste process, we have implemented a comprehensive system for the recovery and recycling of empty grade 5 titanium vials. This material, known for its superior strength and exceptional properties, is crucial for quality assurance in advanced dental applications. Through our system, we guarantee that these vials are sustainably reintegrated into new production processes.

The Recycling System for cardboard boxes and PET plastic blisters

Recycling the plastic and cardboard packaging of DESS Implants has multiple advantages for the environment:

- Significantly reduces waste generation, preventing non-biodegradable materials, such as plastic, from contaminating terrestrial and aquatic ecosystems.

- These materials can be reintroduced into the production chain, reducing the demand for virgin natural resources, such as oil and wood, needed to manufacture new plastics and cardboard.

- Recycling contributes to the reduction of greenhouse gas emissions, since manufacturing products from recycled materials requires less energy than producing them from zero. This helps mitigate climate change and promotes more sustainable practices in the industrial sector.

On the other hand, the Zero Waste DESS process promotes a circular economy, where the materials used have a long life cycle, reducing the environmental impact of medical products.

This philosophy not only protects the natural environment, but also promotes greater ecological awareness in the professional community and among patients, aligning with the global objectives of sustainability and protection of the planet.

Our commitment is your benefit

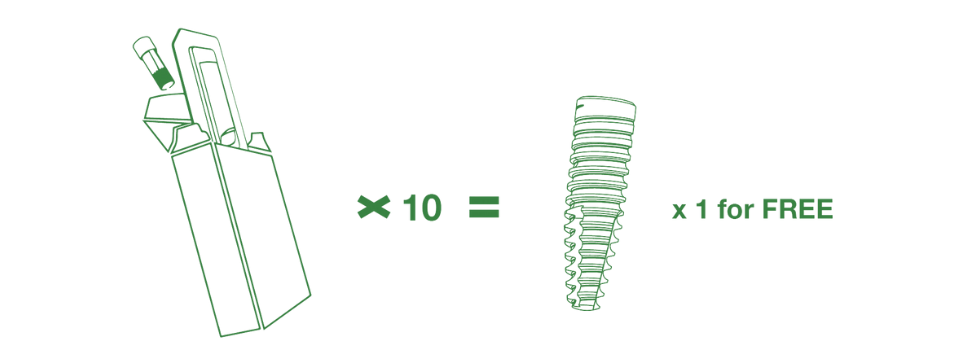

By participating in the Zero Waste process with our implants, the customer becomes an active part of the process, helping us to take care of the Environment, and to reward this help we offer a free implant for every 10 empty packaging returned to us by the clinician.

Grade 5 Titanium Recycling Process

Our recycling system for grade 5 titanium follows carefully controlled steps to ensure its quality:

- Collection of empty vials: We recover the used vials of our DESS Implants, promoting their responsible collection.

- Cleaning and separation: The vials are subjected to a thorough cleaning process and separation of impurities.

- Recycling: If the vials and caps are in good condition, they are sterilized for reuse.

- Smelting and purification: From the discarded vials, the titanium is melted in high-tech furnaces to remove contaminants and guarantee its purity.

- Transformation into grade 5 Titanium: The recycled material is refined and converted into grade 5 titanium, maintaining the properties required for dental manufacturing.

Our Commitment to a Sustainable Future

With our Zero Waste process, DESS reaffirms its vision of uniting sustainability and innovation. By recycling grade 5 titanium and transforming it into useful materials, we reduce the environmental impact and promote a circular economy.

Find out how our innovative approach to recycling is transforming the future. Follow us on social networks and subscribe to our newsletter to be a part of the change. Together we can create a cleaner and more sustainable world!

For more information, please do not hesitate to contact us.